Determine The Soundness Of Cement

The soundness of cement is the ability of the cement to resist volume changes after hardening. The soundness test on cement is significant because the usage of unsound cement leads to development of cracks and hamper the structural quality of the concrete structure. That means the cement should be at minimum volume change after it gets hardened. There for as a practical engineer, you must at all aspects carry out this test and observe all other necessary tests on construction material to prevent collapse and failure of structures, y’all know catastrophic the effect of structural failures.

Why are we calculating this value for cement?

We know that cement is a macro product which consists of 8 micro-ingredients.

- Lime (60%-65%)

- Silica

- Alumina

- Magnesia

- Iron oxide

- Calcium sulfate

- Sulfur Trioxide

- Alkaline

Each has its own set of properties and characteristics in order to make a perfect cement.

As you can see lime is the main product which contributes almost 70%.

Deficiency of lime makes the cement set quicker and affects the property of cement. Meanwhile, the excessive amount of lime makes the cement unsound. It means it cause the cement expands more after it gets hardened.

Soundness of cement by le-chatelier method

(IS:4031-Part 3-1988)

In the soundness test a specimen of hardened cement paste is boiled for a fixed time so that any tendency to expand is speeded up and can be detected. Soundness means the ability to resist volume expansion. The test conducted to identify the excess amount of lime in cement is known as soundness test of cement.

There are two methods available.

- Autoclave Method

- Le-chatelier Method

Object

To identify the soundness of given cement by the le-chatelier method.

Important Terms for Soundness Test of Cement

- Soundness of Cement

Soundness of cement is a measure of the expansion of the hardened cement against the initial expansion. A larger difference indicates the unsoundness of the cement.

- Effective Gauge Length

Effective gauge length is the distance between the innermost points of the metal inserts used as reference points.

Precaution to observe

- All the measurements should be done accurately.

- Temperature of the room and the cement and water used for the test should be 27 ± 2 °C.

- Relative humidity of the laboratory should be 65 ± 5 %.

- Do not apply extra pressure while filling the moulds.

- During boiling water level should not fall below the height of the mould.

Apparatus for Soundness Test of Cement

Soundness test of cement apparatus are listed below:

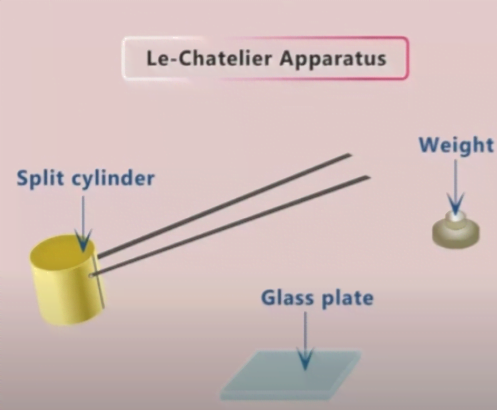

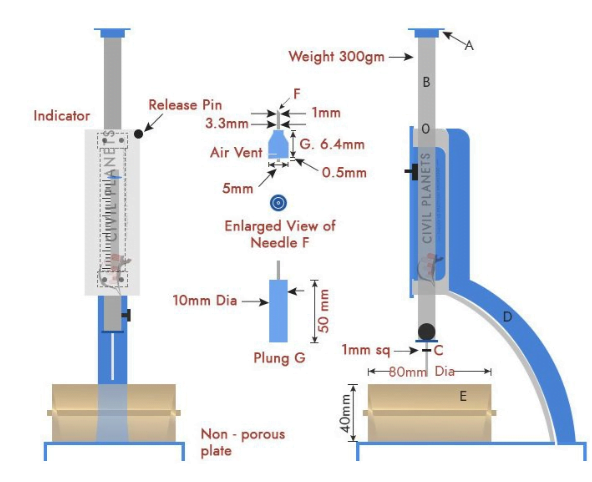

1. Le Chatelier Apparatus

The Le Chatelier apparatus used for determining soundness should conform to IS : 5514 – 1969.

2. Balance

Permissible variation of load at 1000 g = ± 1.0 g

Sensibility reciprocal ≯ 2 Permissible variation

3. Standard Weights

Permissible variation for the weight of cement

4. Water Bath

Water bath should be large enough to immerse the Le Chatelier molds in it.

Furthermore, it should be capable to raise the temperature of water from 27 ± 2 °C to boiling temperature in 27 ± 3 minutes.

5. Trowel

6. Rubber gloves

Materials for Soundness of Cement Test

- Cement – approx. 100 gram

- Oil for greasing

- Water for mixing cement paste

Test Procedure for Soundness of Cement Test

Soundness test of cement procedure is given below:

1. Preparation of Test:

- Prepare cement paste by taking 0.78 P water (0.78 times the water required for standard consistency) {Standard Consistency Test of cement is to be performed to find water required for standard consistency}.

- Lightly oil the mould and the two glass sheets.

- Place the mould on one of the glass sheets.

2. Filling of Mould & Submerging it in the Water Bath:

- Fill the mould with the cement paste.

- Cover the mould with another glass sheet.

- Place a small weight on the top glass sheet.

- Immerse the whole assembly of the mould and glass sheets in the water bath straightaway.

- The temperature of the water bath is kept at 27 ± 2 °C.

- Keep the assembly immersed in the water bath for 24 hours.

3. After 24 hours:

- Measure the distance between the indicator points on the apparatus to the accuracy of 0.5 mm.

- Now immerse the mould and assemble it again in the water as done earlier.

- Raise the temperature of the water to its boiling point in 25-30 minutes keeping the mould assembly immersed.

- Continue boiling the water for 3 hours.

- Remove the mould from the water bath.

- Cool the mould at room temperature.

4. Calculate Expansion

- Measure the distance between the two indicators again.

- Calculate expansion by taking the difference between the distance measured later from the former one.

Observation for Soundness of Cement Test

Observation table for soundness of cement test is given below:

| SI. No. | Description | Test I | Test II |

|---|---|---|---|

| 1 | Initial distance between the indicator points (in mm) L1 |

||

| 2 | Initial distance between the indicator points (in mm) L2 |

||

| 3 | Expansion (L) (in mm) = L1 – L2 |

||

| 4 | Average Value (in mm) |

Calculation for Soundness Test of Cement

Soundness/expansion of cement = L1-L2

L1=Measurement taken after 24 hours of immersion in water at a temp. of 27 ± 20 C

L2=Measurement taken after 3 hours of immersion in water at boiling temperature.

Calculate the mean of two values to the nearest 0.5 mm.

- Note::In the event of cement failing to comply with the specified requirements, a further test should be made from another portion of the same sample in manner described above, but after aeration (done by spreading out to a depth of 75 mm at a relative humidity of 50 to 80% for a total period of 7 days).

Result of Soundness of Cement Test

Soundness for the given cement sample is ______ mm.

Le Chatelier expansion of cement < 10 mm.

Conclusion of Soundness of Cement Test

The given sample of the cement can be concluded to be sound if the expansion is < 10 mm.

If the expansion is ≥ 10 mm, the cement is said to be unsound, which is not suitable for construction.

Technical Discussion

Volume expansion in cement mortar or in cement concrete is caused by the presence of unburnt lime (CaO), dead burnt MgO and also CaSO4.

By Le-chatelier method we can only find out presence of unburnt lime (CaO).

Presence of unburnt lime may develop cracks in the cement because of increase in volume.

Free lime (CaO) and magnesia (MgO) are known to react with water very slowly and increase in volume considerably, which result in cracking, distortion and disintegration.