3 Types of Lintels in Building Construction

A lintel is a structural component used in building construction engineering to support the weight of a load-bearing wall or other vertical loads above an opening, such as a window or door. It is a horizontal beam made of materials such as concrete, steel, or wood that spans the opening and distributes the weight of the structure evenly to the walls or columns on either side.

The difference between a ring beam and a lintel beam is that, the ring beam runs all around the building while the lintel beam is only provided above all openings, its only purpose is to allow continuous safe loading above the opening, this loading is usually a continuous wall, wall plate for the roof and the roof itself.

Lintels can be made of different materials and come in various shapes and sizes to suit different building designs and load requirements. The most common types of lintels used in building construction include reinforced concrete lintels, steel lintels, and wooden lintels.

TYPES OF LINTELS USED IN BUILDING CONSTRUCTION

-

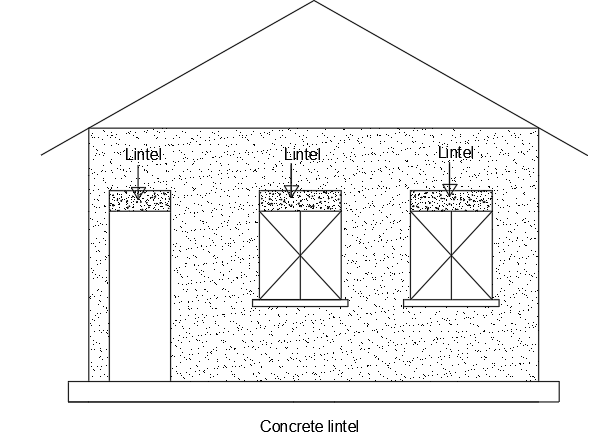

CONCRETE LINTEL

Reinforced concrete lintels are horizontal beams made of reinforced concrete that are used to support loads above openings in building construction. They are commonly used to span over doors, windows, and other openings in load-bearing walls.

The reinforced concrete lintel consists of a reinforced concrete beam, that is designed to distribute the weight of the structure evenly across the walls or columns on either side of the opening. The reinforcement is usually made up of steel bars or mesh, which is embedded in the concrete to increase its strength and prevent it from cracking or sagging under the weight of the load.

Reinforced concrete lintels are preferred in building construction engineering because of their strength, durability, and resistance to fire and corrosion. They are also relatively easy to install and require minimal maintenance.

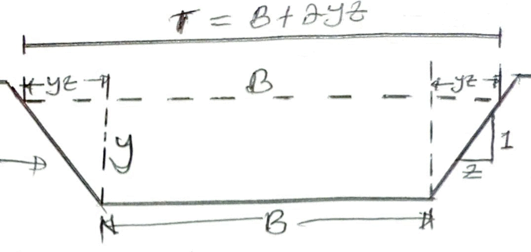

The design of a reinforced concrete lintel will depend on the span of the opening, the load it will support, and the building’s structural requirements. Factors such as the width and height of the lintel, the thickness of the concrete, and the amount of reinforcement required will all be considered in the design process.

-

STEEL LINTEL

They are preferred over other types of lintels in areas where a lightweight and durable solution is required.

Steel lintels are made of different types of steel, including hot-rolled steel, cold-formed steel, and precast steel. Hot-rolled steel lintels are made by heating steel billets to high temperatures and then rolling them into shape. Cold-formed steel lintels, on the other hand, are made by bending and shaping steel sheets without heating them. Precast steel lintels are made off-site and then transported to the construction site for installation. The most preferred shape of steel section for lintels are the I-section steel.

Steel lintels are typically more expensive than other types of lintels but are preferred in building construction engineering for their strength, durability, and resistance to fire and corrosion. They are also easy to install and require minimal maintenance.

The design of a steel lintel will depend on the span of the opening, the load it will support, and the building’s structural requirements. Factors such as the width and height of the lintel, the thickness of the steel, and the number of supports required will all be considered in the design process.

-

TIMBER LINTEL

Timber lintels are horizontal beams made of timber, that are used in building construction engineering to support the weight of the structure above smaller openings such as doors and windows. They are typically used in traditional construction and are still used in some modern buildings, particularly in low-load areas.

Timber lintels are not as strong as reinforced concrete or steel lintels, but they are relatively easy to work with, lightweight, and cost-effective. They are also environmentally friendly as timber is a renewable resource.

The design of a timber lintel will depend on the span of the opening, the load it will support, and the building’s structural requirements. Factors such as the width and height of the lintel, the thickness of the timber, and the number of supports required will all be considered in the design process.

Timber lintels must be treated with preservatives to protect them against decay, insect infestation, and fire. They are also susceptible to moisture and can warp or rot if not properly maintained.

Advantages of reinforced concrete lintels over steel lintels in construction

Strength: Reinforced concrete lintels are stronger than steel lintels and can support heavier loads without bending or sagging. This makes them suitable for use in areas with high load requirements.

Durability: Reinforced concrete lintels are more durable than steel lintels and can last for many years with minimal maintenance. They are resistant to fire, weather, and corrosion, making them ideal for use in harsh environments.

Cost: Reinforced concrete lintels are generally less expensive than steel lintels, particularly for smaller openings. This makes them a more cost-effective solution for many building projects.

Ease of Installation: Reinforced concrete lintels are relatively easy to install and do not require specialized equipment or tools. They can be cast on-site or precast off-site, making them suitable for use in a wide range of building projects.

Design Flexibility: Reinforced concrete lintels offer more design flexibility than steel lintels as they can be cast into a variety of shapes and sizes to suit different architectural requirements.

Factors influencing the choice of material for lintels.

Before designing and determining the choice for lintel beams, you need a thorough analysis of the impacts especially on loadings on the beam and choose appropriately, the factors below influence the choice of material or lintel beam required.

Load requirements: The type of material used for lintels will depend on the size of the opening and the load it will support. Heavy loads may require reinforced concrete or steel lintels, while lighter loads may be adequately supported by timber or other materials.

Building codes and regulations: Building codes and regulations may specify the type of material that must be used for lintels based on safety and performance standards. For example, in areas with high fire risk, steel or concrete lintels may be required.

Cost: The cost of materials is also an important factor when choosing lintels. Some materials, such as reinforced concrete and steel, may be more expensive than others, such as timber or masonry.

Aesthetics: The choice of material for lintels can also be influenced by aesthetic considerations. Some materials, such as timber, may be preferred for their natural appearance, while others, such as steel or precast concrete, may be preferred for their sleek and modern look.

Maintenance requirements: The maintenance requirements for different materials can also influence the choice of lintel material. Some materials may require regular maintenance, such as treatment with preservatives or coatings to prevent decay or rust, while others may require minimal maintenance.

Availability: The availability of materials may also be a factor when choosing lintel materials. Some materials may be more readily available than others in certain regions, which can affect their cost and suitability for use.

Under what conditions should

you use lintel beams over ring beams.

Lintel beams and ring beams are both structural elements used in building construction engineering to support the weight of a structure. Lintel beams are horizontal beams placed over openings such as doors and windows to support the weight of the wall above, while ring beams are horizontal beams that encircle the entire perimeter of a building to provide additional support.

The choice between using lintel beams and ring beams will depend on several factors, including the size and load requirements of the opening, the type of wall construction, and the local building codes and regulations.

In general, lintel beams are typically used for smaller openings such as doors and windows, where the load requirements are relatively low. They are usually made of steel, reinforced concrete, or timber and are placed directly over the opening. Lintel beams are cost-effective and easy to install and are often used in residential and low-rise commercial buildings.

On the other hand, ring beams are typically used in larger structures or in areas with high seismic activity. They provide additional support and help to distribute the weight of the building evenly. Ring beams are usually made of reinforced concrete and are designed to encircle the entire perimeter of the building, creating a continuous load-bearing structure.