Standard Consistency of Cement paste.

The theory

Standard Consistency of Cement paste is defined as that consistency which will permit a vicat plunger having 10 mm diameter and 50 mm length to penetrate to a depth of 33-35 mm from top of the mold.

The purpose of this test is to find out the initial setting time, final setting time and soundness of cement and strength of a parameter known as standard consistency has to be used.

Apparatus

Vicat apparatus IS:5513, Balance 100g, Gauging Trowel, Measuring Cylinder 100ml, Stopwatch, Tray, Glass plate, etc.

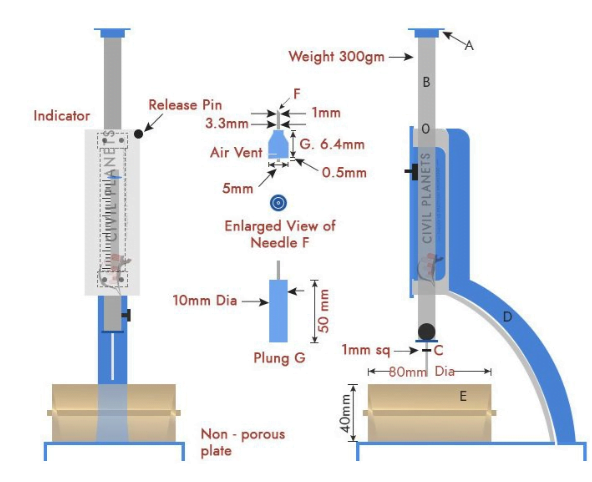

Vicat Apparatus

The vicat apparatus consists of a frame having a movable rod with a cap at one end and at the other end any one of the following attachments, which are interchangeable:

- Needle for determining the initial setting time

- Needle for determining the final setting time

- Plunger for determining the standard consistency

. Needles

Needle for Initial Setting Time The needle is having a cross sectional area of 1mm2. The end of the needle is flat. Needle for Final Setting Time The needle is circular having a cross sectional area of 1mm2. The needle is fitted with a metal attachment. The end of the needle projects beyond the cutting edge of the hollowed-out metal attachment. Plunger for Standard Consistency It is of polished brass 10 ± 0.05mm in diameter with a projection at the upper end for insertion into the movable rod. The lower end is flat.

Movable Rod

Movable rod carries an indicator which moves over a graduated scale attached to the frame (certain models have an additional attachment of dash pot, which facilitates lowering of movable rod slowly).

Graduated Scale

Graduated scale is 40mm in length and the smallest division of scale is 1mm.

Vicat Mould

Single mould the vicat mould is in the foam of a frustum of a cone having an internal diameter of 60+/-0.5mm at the top, 70 +/- 0.5mm at the bottom and height 40 +/_ 0.5mm. Split type vicat mould the split type vicat mould is used as an alternative to single mould. This mould consists of a split ring having an internal diameter 80+/- 0.1mm and a height 40+/_0.5mm. A non-porous base plate is provided. The split mould is provided with a suitable clamping ring.

Environmental Conditions

27 ± 2°c Temperature

65 ± 5% Temperature

Procedure for Standard Consistency of Cement paste

- Keep the vicat apparatus on a level base (when using vicat apparatus with dashpot, keep the bearing movable rod to its highest position and pin it.) Unscrew the top of the dashpot. Half fill the dashpot with any suitable oil of viscosity and screw the top. Work the plunger a number of times.

- Attach the plunger for determining standard consistency to the movable rod. Work the plunger a number of times.

- Take 400 gm of cement in a pan and a weighed quantity of water in a beaker.

- Prepare a paste with the water added to cement. Start a stopwatch at the time of adding water to cement.

- Keep the vicat mould on a non-porous plate and fill the cement paste in it.

- After completely filling the mould, shake it slightly to expel the air. Smooth off the surface of the paste making it level with the top of the moulder. The cement pastes thus prepared is the test block.

- Place the test block resting on the non-porous plate under the movable rod, bearing the needle.

- Lower the plunger gently to touch the surface of the cement paste and quickly release; (when vicat apparatus with dashpot is used, place the mould filled with cement paste and the non-absorbent plate on the base plate of the vicat apparatus. Raise the plunger of the dash pot, bring it in contact with the top cap of the movable bearing rod.

- Remove the pin holding the movable bearing rod to the surface of the cement paste and quickly release by pushing down the plunger to sink in to the paste). This operation shall be done immediately after filling the mould.

- Prepare trial test specimens with varying percentages of water until plunger penetrates to a point 5 to 7mm from the bottom of the vicat mould, which is read on the scale. Express the water required as percentage by weight of the dry cement

Observations and Calculations

- Weight of cement taken (g) = _________

- Initial percentage of water added to cement = __________

- Quantity of water added to cement =_______

Table

| SL. NO. | QUANTITY OF WATER ADDED (ml) | DEPTH OF PENETRATION (mm) |

Standard Consistency of Cement = (Quantity of water for 5-7 mm penetration/Weight of cement) X 100

Results

Percentage of water content for standard consistency = %

Points to be Noted

- The time of gauging should not be less than 3 minutes and not more than 5 minutes. Gauging time is the time elapsing from the time of adding water to the dry cement until commencing to fill the mould.

- The test should be conducted at room temperature 27oC +/- 2oC

- There should be no vibration on the working table.

- The plunger should be cleaned during every repetition.

Precaution

- Gauging time should be strictly observed

- Room temperature should be well maintained as per test requirement.

- All apparatus used should be clean.

- The experiment should be performed away from vibrations and other disturbances.

Test standard reference

IS:4031(Part 4):1988-Methods of physical tests for hydraulic cement (Determination of consistency of standard cement paste.

Reference: Consistency Test of Cement IS Codes – IS: 5513-1976, IS: 4031 ( Pat 4 ) – 1988,

Importance of Standard Consistency of Cement paste test.

The consistency test of cement is an essential test that determines the amount of water required to make a cement paste of standard consistency.

It helps in achieving the desired workability and strength of the concrete mix. The test is performed to ensure the consistency of the cement paste, which is necessary for its proper hydration and subsequent strength development.

What are the factors that can affect the Consistency Test of Cement?

The factors that can affect the Consistency Test of Cement include the type and brand of cement, the temperature and humidity of the testing environment, and the method used to mix the cement and water.

Who can perform the Standard Consistency of Cement paste?

The Consistency Test of Cement can be performed by trained technicians or engineers who are familiar with the equipment and procedures involved. The test is typically conducted in a laboratory setting.

What is the Standard Consistency of Cement paste?

The standard consistency of cement paste is typically defined as the consistency at which a standard Vicat needle penetrates a cement paste to a depth of 5-7 mm.