Concrete

What is concrete

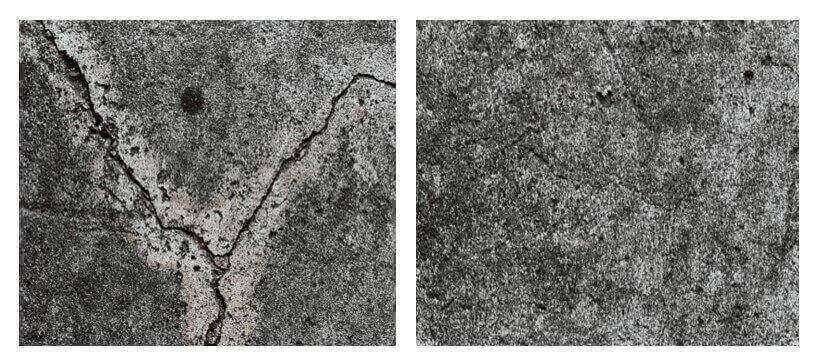

Concrete is a building material made by mixing cement, fine aggregates/sand, coarse aggregates/gravel with water and allowed to hardened to get a solid material. if concrete is produced in its appropriate standards, then concrete can be a durable, watertight and highly compressive building material. Fresh concrete is usually posses fluid-like form which enables the hardened form to be achieved in different forms by the aid of a suitable form work. Quality control is essential prior to and post placement of concrete.

Application of concrete

-

Reinforced concrete buildings/bridges

Concrete is mostly used in construction of reinforced concrete structures, such as columns/abutments, slabs/decks, beams, staircase, ramp, shear wall, etc. The concrete is casted directly into already created formwork, compacted, cured and formwork removed to form the solid hardened concrete, formwork maybe removed after a week before completion of curing or after curing.

-

Precast Building components.

During modular constructions, concrete can be used to produce these precast components such as columns, slabs, beams, toilet slabs, wall units, etc. These components are produced in a workshop or in a factory. They are usually produced to high standard with the right constituent proportioning and accurate required level of curing, and transported to the site for assembling, read more about precast units.

-

Precast decorative units

Concrete can be used to make precast decorative units, animals, pots, seats etc. These items are usually produced either by manually modelling or using suitably designed formworks. For monumental/animal structures, they are usually modeled manually, other items like pots are usually modelled in a formwork etc.

-

Structural footings

When it comes to structures such as buildings, bridges, dams, wells, steel structures, tunnels, culverts, etc there foundation structures are supported beneath with reinforced or plain concretes, due to the reason that concrete is a good compressive material and able to transmit the loads to soils uniformly and creates a firm base, this can be inform of pad footings, strip footings, raft, grillage etc.

Material Advantage Of Concrete

- Concrete can be used any where due to the fact that its ingredients are readily available

- it is extremely flexible building material, capable of taking virtually any shape

- As a material, it is strong as natural stone, it is durable and resistant to the elements

- It requires a minimum of highly skilled laborer to mix and place

Concrete ingredients

-

Portland cement

Portland cement is manufactured from lime, silica, iron oxide and alumina. in its dry state, Portland cement is a very fine powder. When mixed with water, a paste is formed , as it hardened the paste looses its plasticity.

The initial setting occurs in about one hour and the final setting in ten hours, the cement however continues to harden until its full strength after 28days. the Portland cement paste is the one used to bind the fine and the course aggregates.

-

Fine aggregates

- Consists of sand and other suitable fine material

- fills the spaces between the coarse aggregates

- Fine particles are necessary to allow for good workability and smooth surfaces when hardened

- An excess of fine aggregates requires an increase in cement, increasing cost and overall shrinkage of the mix.

-

Coarse aggregate

- Consists of crushed stone or gravel larger than the fine aggregates, but small enough to fit between reinforcement bars

- Should be hard and durable as opposed to soft and flaky

-

Water

- Water must be clean from oil, alkali, acid etc. Simply it should be drinkable.